How to Ensure Reliability and Durability in RF Circuit Boards

admin

- 0

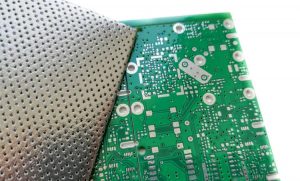

Reliability and Durability in RF Circuit Boards

In an age of wearable tech, tinier electronic devices, and more, RF circuit boards are becoming denser and smaller. As a result, the development of new PCBs must keep up with demands for higher performance and increased connectivity. The future of rf circuit board development must also consider heat levels, power consumption and more. Here are some of the most significant trends in this area to look out for.

Advanced nanometer CMOS technology is making it possible to use low-voltage operation in RF and mm-wave circuits. These ICs are capable of using techniques like transistor body biasing and flipped-well LVT transistors for lower voltage operation than conventional n-MOS topologies. Modified circuit topologies and transformer-based power combining are additional effective strategies for lowering supply voltages.

These changes allow for high-performance RF/mm-wave integrated circuits (ICs) with greater efficiency and lower power consumption than previous technology. It also allows a single device to operate at different frequencies and enables the elimination of planar high-Q ceramic filters – another big SWAP-C savings. The next step will be to enable the use of digital signal processors for RF sampling at higher sample rates, moving closer to software defined radio, where each component can be optimized by the user for their particular frequency schemes and performance tradeoffs.

How to Ensure Reliability and Durability in RF Circuit Boards

With more and more consumers demanding connected smart devices, the focus will be on devices that work continuously with no need for human intervention. This will drive the design of rf circuit board that consume less energy and draw power from a variety of sources, including batteries, solar cells, and electricity-harvesting components. In addition, the use of power-efficient RF chips with reduced parasitics and losses will help to further reduce power consumption.

A key part of any RF circuit board is its ability to handle the high temperatures associated with high-performance technologies like ultra-wideband transmitters and radar modules. As a result, it’s important to conduct a thermal analysis of your design and make sure that all components are in their correct power states and don’t generate excessive heat. This will require collaborating with electrical engineers to ensure that integrated circuits can enter their power states when needed, and it’s also vital to ensure there is enough copper underneath your components to maintain an adequate current path.

RF circuit boards, also known as radio frequency circuit boards, are crucial components in modern electronic devices designed for wireless communication, radar systems, and various other applications that involve radio frequency signals. These specialized circuit boards play a pivotal role in ensuring efficient transmission, reception, and processing of high-frequency signals with minimal loss and interference.

Lastly, it’s worth considering the use of lead-free laminates to cope with the increased heat that some of today’s devices must deal with. These materials offer better corrosion resistance and avoid the toxic puddles of liquid metal that can form on older devices, especially when they’re subjected to long-term exposure. In addition, they allow the underlying circuitry to cool down more quickly and reliably, so that you can keep your RF circuits performing at their best.